Technology, sustainability, and consultancy at the service of modern industry and construction

In an industrial landscape that is constantly evolving—driven by ecological transition, digitalization, and new market demands—Hydro Extrusion Italy stands out as a solid and dynamic force, capable of blending Italian manufacturing heritage with the strength and vision of a global group. The two Italian plants, located in Ornago (MB) and Feltre (BL), form the productive core of the Italian division of Hydro, a Norwegian company with over a century of experience in aluminum processing and renewable energy production.

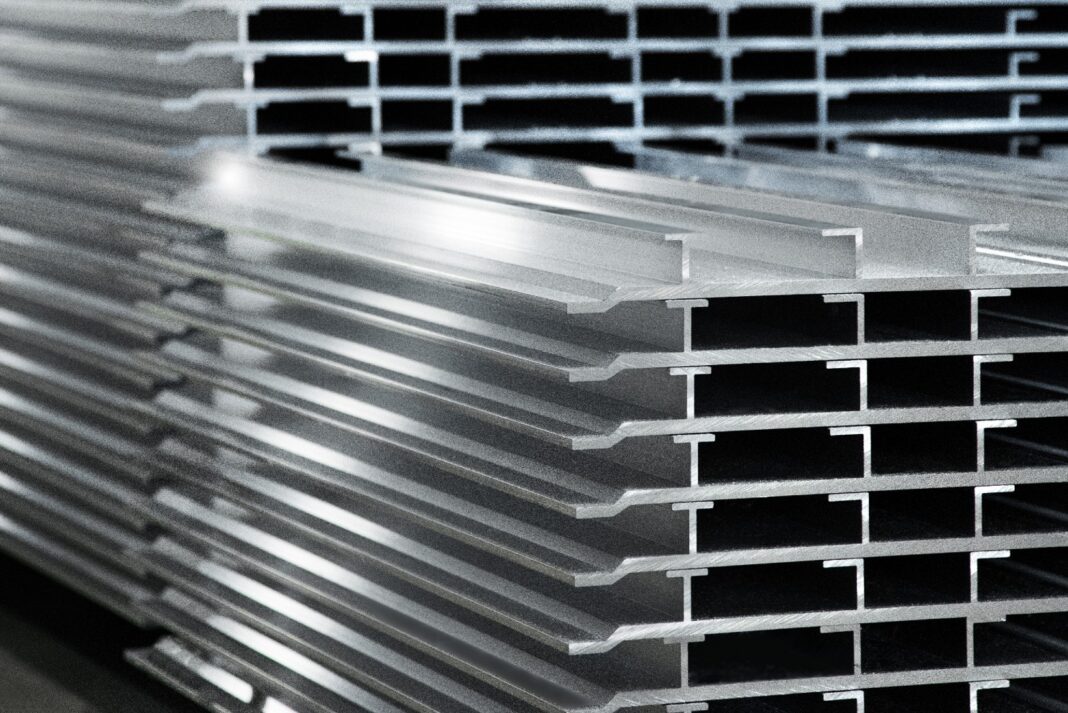

Hydro is not just a global manufacturer; it is a vertically integrated group active throughout the entire aluminum value chain—from Brazilian bauxite to finished profiles ready to be turned into architectural, automotive, or industrial components. Within this value chain, Italy plays a key role: with an annual capacity of 45,000 tons of extruded profiles and a 50,000-ton recycling billet foundry, Hydro Extrusion Italy ranks as a national industry leader.

From local roots to global structure: a tale of two plants

Each of the two Italian sites brings a distinct history that reflects the evolution of the aluminum sector. The Feltre plant, active since the 1940s, was originally established to support wartime production during WWII. It later transitioned to aluminum processing and then evolved into a key recycling hub. Today, it is a highly technological site, playing a strategic role in sustainability through its integrated foundry.

Ornago, in the province of Monza and Brianza, has more recent origins but is equally significant. Founded in the 1960s as an Italian entrepreneurial venture, it became part of Hydro through a series of acquisitions. Today, it is one of the most advanced production centers for mechanical and surface treatments of extruded profiles. Both plants were part of a joint venture with SAPA until 2017, the year Hydro acquired the full extrusion operations, reinforcing its global presence.

From concept to product: aluminum as a tailor-made service

One of the hallmarks of Hydro Extrusion Italy is its consultative approach. As Stefano Spinelli, Sales & Marketing Director for Italy and France, explains:

“We don’t manufacture off-the-shelf products. We bring our customers’ ideas to life. They come to us with a concept, a design, a requirement—and we support them through the entire development process. From engineering to alloy selection, surface treatment, and end-of-life planning.”

Stefano Spinelli, Sales & Marketing Director for Italy and France.

This means co-engineering, technical support, and structural and economic optimization, often leveraging the group’s innovation center in Sweden. Every day, Italian engineers and project managers collaborate with architects, designers, and R&D teams across industries to turn aluminum into a competitive, sustainable, high-performance asset.

Cross-industry presence: from mechanics to construction

One of Hydro’s major strengths is its presence across a wide array of industries. The Italian client portfolio includes brands in furniture, windows and doors, mechanical engineering, electrotechnics, transportation, and components. Aluminum applications are everywhere: handles, table legs, kitchen parts, curtain walls, structural profiles for commercial vehicles, or photovoltaic systems. “Our strength lies in our balance,” notes Spinelli. “We’re not dependent on a single industry. This gives us resilience during downturns in any one sector. Diversification allows us to adapt quickly and recalibrate our production with agility.”

Focus on construction and high-efficiency materials

Historically, around 50% of extruded aluminum in Europe is used in the building sector. From ventilated facades to lightweight structural frames and designer finishes, modern construction relies on aluminum for its lightness, durability, corrosion resistance, and workability. As environmental regulations evolve and demand for circular materials grows, aluminum plays an increasingly central role in energy-efficient architecture.

Hydro offers certified materials with full traceability and Environmental Product Declarations (EPDs) that meet LEED, BREEAM, and CAM sustainability standards. Transparency is an integral part of the customer relationship.

Sustainability that’s real and measurable

Hydro was one of the first companies in the industry to implement a structured sustainability roadmap, launched in 2018. The plan targets a 30% emissions reduction by 2030 and net-zero emissions by 2050. Supporting this vision, Hydro invests in low-carbon alloys produced with its own hydropower and post-consumer recycled materials.

“Some of our alloys now contain 100% post-consumer recycled content,” explains Andrea Baiamonte, Business Development Manager at Hydro. “And they maintain the same mechanical performance as primary materials. This is possible only because we apply a tightly controlled and certified recycling process.”

Hydro also develops closed-loop projects, where products are designed for disassembly, reuse, and remelting, minimizing environmental impact at the end of their lifecycle.

A competitive market, a valuable response

Italy’s installed aluminum extrusion capacity far exceeds domestic demand. The market is populated by numerous players, many of them family-owned. In this crowded landscape, Hydro stands out through the quality and reliability of its service: design support, consultancy during the development phase, sustainability analysis, and consistent production—even during market disruptions. “We don’t just deliver a part,” emphasizes Spinelli. “We act as a partner, providing support with design, alloy selection, and end-of-life calculations. This service-driven approach sets us apart and fosters long-term relationships.”

Continuous innovation and local engagement

Hydro’s commitment goes well beyond the factory floor. Its Italian division is highly active in client engagement and education—from roadshows and university collaborations to sustainability and circular economy initiatives. This ongoing dialogue fuels both innovation and trust.

Hydro Italy is more than a manufacturing site. It is an open, competent, and sustainable industrial ecosystem—a proactive player in the Italian market and a strategic partner for the future.

Hydro is here. And looking ahead.

At a time when many industries face uncertainty, Hydro Extrusion Italy reaffirms its presence with a clear promise: continuity, reliability, expertise, and sustainability. This is the foundation behind every extruded profile from Ornago or Feltre—ready to become part of a skyscraper, a vehicle, a home. Ready, ultimately, to become part of our shared future.