A franchising model to multiply plants, margins and investment opportunities

“What McDonald’s did for the food industry, we want to do for construction.” With this bold and visionary statement, Zeeshan Ahmed, CEO and founder of Zavhy, encapsulates the mission of the spin-off born from his PhD at Eindhoven University of Technology (TU/e). Today, Zavhy is one of Europe’s most promising startups in the field of 3D concrete printing (3DCP).

From academia to the marketplace

The idea, Zeeshan explains, didn’t come by chance. “When I started my PhD in 2015, I already knew I wanted to bring this technology to market. In academia, even a wrong answer can lead to discovery. In industry, a wrong answer is just wrong, and it can cost you the next project or round of funding. That’s why I pursued my research with a clear purpose: to turn it into the foundation of a real business.”

His journey began in London, where in 2013 he specialized in 3D plastic printing for architecture. But the real challenge came with concrete, the material that symbolizes modern construction. In 2015, he embarked on a PhD in the Netherlands with a clear vision: to transform research into a company. “From the very beginning, I knew I didn’t just want to publish papers, I wanted to build the foundation for an industrial technology.”

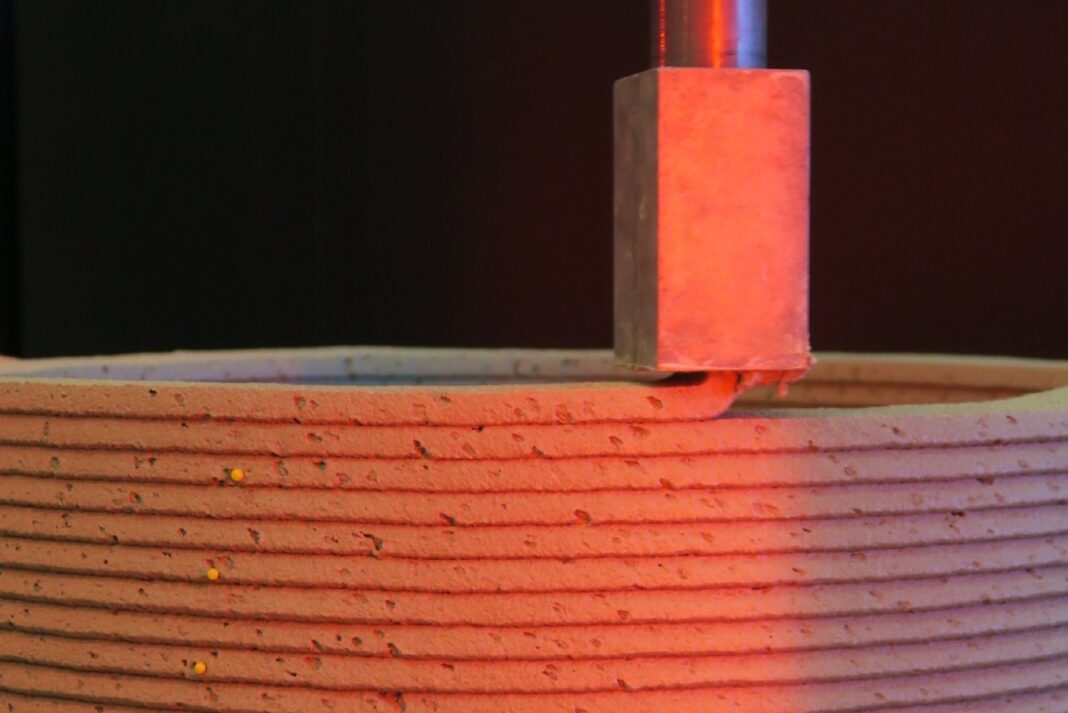

During his doctoral years, Zeeshan focused on one of 3DCP’s biggest limitations: the lack of reinforcement and additives to make printed structures competitive with conventional concrete. Out of this came the two devices that remain at the core of Zavhy’s technology today: RED (Reinforcement Entrainment Device) for embedding steel cables, and FRED (Fibre Reinforcement Entrainment Device) for fibers and aggregates.

A technology that changes the rules

“While many are still printing with cementitious mortar, we’ve developed an integrated hardware and software system that enables us to print structural-grade concrete, enhanced with fibers, coarse aggregates, chemical additives, and reinforcement. By carefully controlling every stage of the process and monitoring each parameter, we ensure that every element we produce is both precise and genuinely robust. This makes our technology flexible and adaptable to every market,” Zeeshan explains. The result is Zavhy’s micro-factory, a platform designed to adapt to different requirements from testing seismic resistance 3DCP structures to adopting circular and sustainable 3DCP applications.

The real change isn’t just about technology, it’s about how we think. I often align with architects and engineers that share the perspective that 3D printing asks us to rethink the design to materialization process. Instead of starting with a finished design and then forcing the technology to follow, we begin with what the material and machine can do, set those boundaries, and let creativity take shape within them.

This represents a fundamental shift in thinking, not the end of creativity, but a new way to guide it. It’s like choosing the right tool: you wouldn’t use a screwdriver to hammer a nail, or a hammer to drive a screw. 3D printing is simply another tool, one that architects and engineers are learning to work with. It doesn’t limit creativity; it just invites a different kind of freedom.

Value beyond design

The added value, however, goes beyond design. With construction still lagging in digitalization, burdened by labor shortages and a massive CO₂ footprint, Zavhy offers a tangible solution: shorter construction times, higher margins, and improved sustainability. “For example, if building a wall is worth €100, usually the material cost will be around €10, with €10 to €15 in margins, and €75 to €80 in labor costs. With our technology, we drastically cut those labor costs, potentially improving the margins for projects,” Zeeshan notes.

Results quickly followed. After contributing to the first 3D-printed bridges in Gemert and Nijmegen, and to the iconic Milestone house in Eindhoven during his PhD research, Zavhy opened a dedicated 3DCP facility in 2024. “We are currently working on three prototype bridges funded by the Netherlands Enterprise Agency (RVO), Ministry of Economic Affairs and Climate (EZK) and Ministry of Infrastructure and Water Management (IenW). The first bridge using 3D concrete printed molds to reduce formwork costs, second with integrated fibers and reinforcement to improve performance, and a third designed to be disassembled and reused,” Zeeshan explains.

This project aims to develop 3D-printed concrete bridges that are structurally sound, cost-efficient, and materially sustainable, demonstrating their value to both municipalities and investors. Not surprisingly, Zavhy’s five-year roadmap includes the construction of 60 bridges using its technology with its partners Remmits GWW and IMd Raadgevende Ingenieurs.

Sustainability and circularity

The environmental case is just as important. “Construction is one of the most polluting industries: too much cement, too many single-use molds, too much waste. We cut cement use by replacing it with alternative binders, we eliminate molds thanks to 3D printing, and we add sensors for predictive monitoring. In the end, durability is what makes a bridge truly sustainable, it’s better to build one that stands for 100 years than to rebuild it every few decades.”

Social impact is also part of the vision. More automation means less physically demanding sites, safer conditions, and the inclusion of new skills and professionals including women, in a traditionally male-dominated sector.

Why invest in Zavhy’s technology

Beyond sustainability and efficiency, Zavhy’s technology delivers direct benefits to those who adopt or invest in it. “We don’t want to be the only ones printing bridges or houses — we want to create an ecosystem where others can open micro-factories, leverage our patents, and build on validated technology,” Zeeshan emphasizes.

The main advantages for investors and adopters are threefold:

Lower labor costs: 3D printing can cut up to 40% of labor expenses, turning wafer thin margins into substantial profits.

Certified know-how: adopting Zavhy’s 3DCP technology to deliver construction projects, customers gain access to structures already compliant with European standards, reducing risks around permits and approvals.

Rapid scalability: the franchising model provides technical support, certified materials, and pre-validated designs, enabling faster go-to-market than independent innovation. Making 3DCP technology more accessible and affordable.

“It’s a unique opportunity,” Zeeshan stresses. “We’re not talking about a distant promise — this is a technology already tested, validated and applied in real projects. Investing in Zavhy means investing in an industry poised for exponential growth.”

From franchising to artificial intelligence

And the future? Here Zeeshan often turns to food metaphors. “Think of pizza: once, everyone made their own. Today, chains like Domino’s have standardized an acceptable level of quality. We’re not here to replace craftsmanship, but to make a replicable model available everywhere.”

The vision is clear: a franchising model for construction. From the Netherlands to India, anyone can open a Zavhy facility, purchasing certified printers, concretes and fibers. This way, Zavhy is not just a builder, but a global technology enabler.

Alongside franchising, the startup is working on a European project funded by European Union and co funded by Dutch national government for OPZuid and province of North Brabant. The project sets the technological foundations to integrate machine learning and artificial intelligence. “Every stage of printing generates valuable data: from quality control to design decisions. Today we are in the phase of data-driven design, tomorrow we’ll move into machine learning, and eventually AI will be able to optimize the entire process.” Zavhy, together with its partners AGMAH and Qugate, aims to complete this phase of the development by 2026.

Ten years after first exploring 3D concrete printing, Zavhy embodies a journey of research, innovation, and entrepreneurial persistence. From RED and FRED to bridges in the Netherlands, from circular design to the prospect of global franchising, Zeeshan Ahmed’s company aims to radically transform a conservative and resource-intensive industry.

“Our goal is straightforward: to build faster, better, and with less impact on the planet and, in the long run, to make safe, sustainable housing and infrastructure accessible to everyone.”

The Zavhy team: Taco Westerouen van Meeteren, Wendy Volkers, Zeeshan Yunus Ahmed