Founded in 1875 in Aalen, southern Germany, RUD Ketten Rieger & Dietz GmbH u. Co. KG has grown into a global player with over 1,700 employees, active in more than 120 countries, and generating an annual turnover of around 200 million euros. The company is renowned for its high-performance steel chains and its ability to turn them into technological solutions that go far beyond mechanical components. Its portfolio covers lifting and lashing technologies, protective systems, and, above all, industrial drive and conveying applications.

On the occasion of the launch of the latest innovations in the TECDOS series, we spoke with Rupert Wesch (Head of Applications Engineering), to explore how research and development drive the company’s strategy and how two flagship products — Pi-Gamma and Omega Drive — open up new possibilities in industrial automation and motion technology.

What philosophy drives RUD’s Tecdos solutions?

“Our mission is to turn what seems like a simple technology — the steel chain — into the core of flexible, safe and durable drive systems. The chain is the heartbeat of all our drives: it withstands better sand, water, ice, dirt, and extreme conditions where other solutions such as racks or spindles often fail. The outcome is better operational reliability and longer service life, which are critical in sectors like offshore, steel production or heavy logistics.”

Pi-Gamma is often described as an ‘all-rounder’. Why?

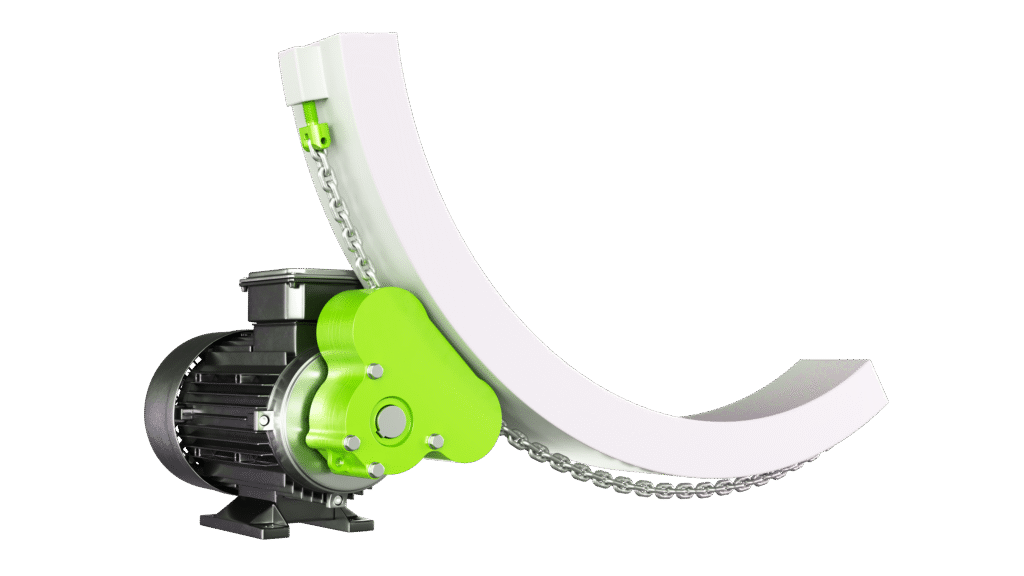

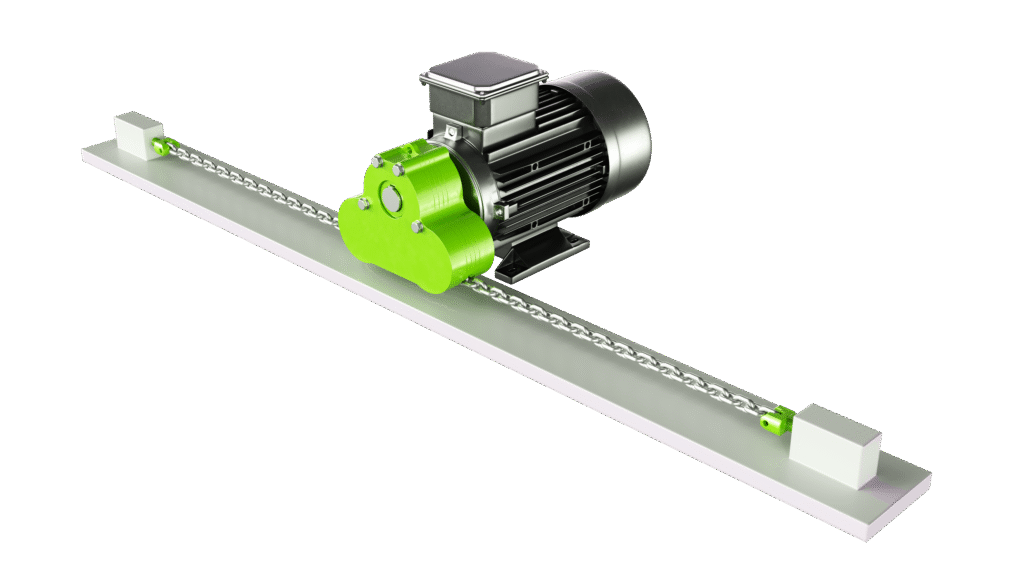

“Pi-Gamma is a 2-in-1 drive system that can act both as a head drive and as a deflection module. Its distinctive feature is the chain deflection, which ranges from 90 to 180 degrees.

This makes it suitable for horizontal, inclined or vertical applications: from blast furnace closures to large industrial gates or gangways in harbour facilities. Thanks to its modular design, the system is available in seven standard sizes and can be combined in multiple configurations. In practice, there are virtually no limits to its application.”

And what about Omega Drive? How does it differ?

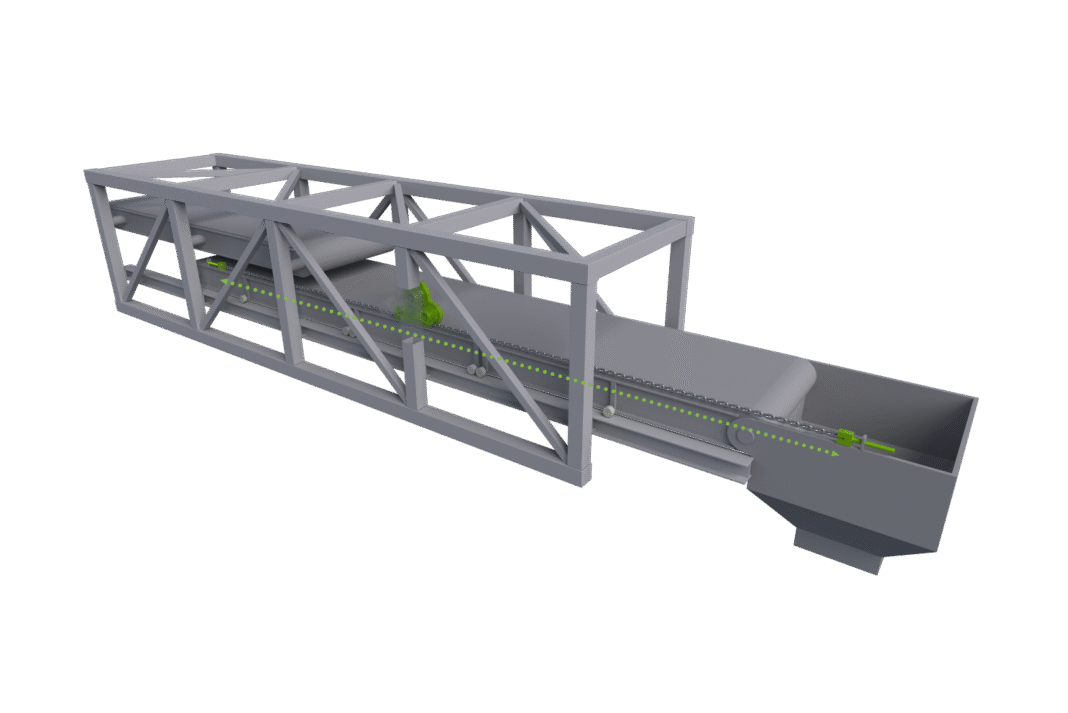

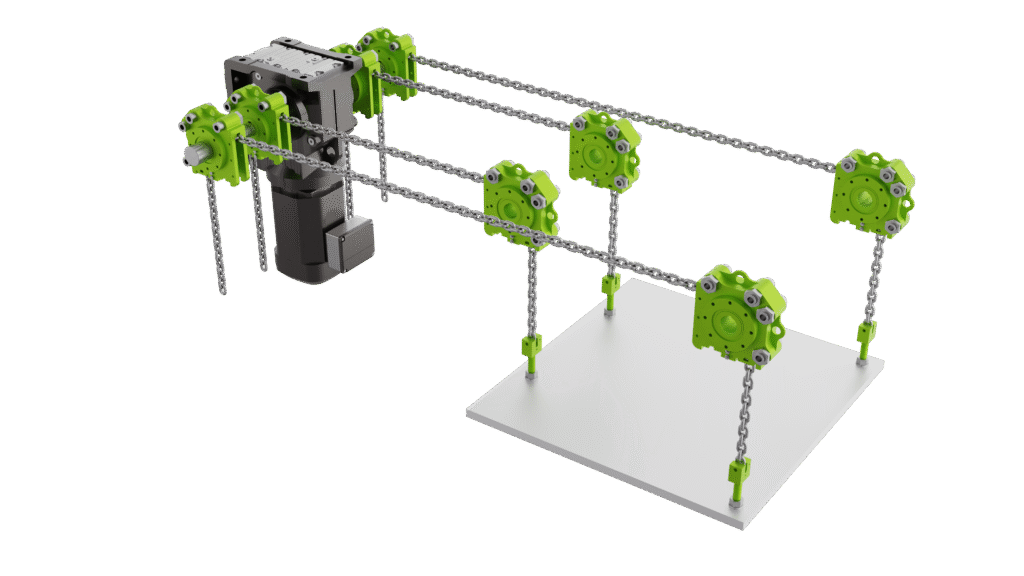

“Omega Drive is designed for both linear and rotary movements. Its name comes from the 180-degree wrap angle that defines the system. Three deflection wheels arranged in a triangular formation guide the chain smoothly, while avoiding any reaction forces on the drive. This means compactness, easy installation, and the ability to operate in confined spaces where winches or racks cannot be used. It is the approved solution for harbour cranes, moving machinery, or solar tracking systems.”

What added value do you see for universities and research centers?

“Many of our systems are developed in cooperation with research institutes and industrial partners. The modular and scalable nature of Tecdos allows universities and tech spin-offs to test customized solutions that can then be scaled up for industrial use. Moreover, our high-performance steel chains are certified to withstand extreme conditions, which is crucial for prototypes in energy, maritime or aerospace applications. We see ourselves not only as component suppliers but as innovation partners.”

How do sustainability and innovation come together in your projects?

“Sustainability is also about durability and reliability. A drive that keeps running under critical conditions reduces maintenance, extends lifecycle, and prevents waste. This translates into less material, lower energy consumption, and higher efficiency for our customers.”

The Tecdos Pi-Gamma and Omega Drive range shows how applied research can transform a traditional product into a high-tech system capable of supporting complex and strategic industries. For universities and companies seeking a reliable technology partner, RUD exemplifies how innovation, tradition, and collaboration can converge into solutions with tangible impact on the industry of the future.